- Coverall

- PP coverall

- TYPE3B TYPE4B TYPE5B TYPE6B coverall

- TYPE5 TYPE6 coverall

- TYPE5B TYPE6B coverall

- TYPE4B TYPE5B TYPE6B coverall

- Reflective coverall

- Flame retardant coverall

- Coverall with visible windows

- Coverall with cool back

Knowlege you may like to know about disposable coveralls(3)

For nonwoven coveralls, there are always four types on seams as following

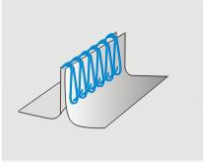

Stitched seam is most common, some like to call serged seam.This is an standard 4thread overlocking technology, which offers an excellent balance of a strong seam with good particle barrier.Iternal stitching reduces the risk of any potential linting from the thread.Serged seams are generally used on garments for light splash and dry particle protection. Safety coveralls for basic protection usually made with serged seam.

Stitched seam is most common, some like to call serged seam.This is an standard 4thread overlocking technology, which offers an excellent balance of a strong seam with good particle barrier.Iternal stitching reduces the risk of any potential linting from the thread.Serged seams are generally used on garments for light splash and dry particle protection. Safety coveralls for basic protection usually made with serged seam.

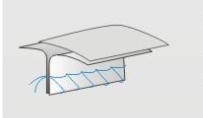

Stitched seam&taped seam, the seam is first stitched and sealed on the outside with a heat activated tape.This results in increased strength and an effective barrier to liquids and particulates.Disposable protective coveralls for medical/hospital/oil and painting industry will always need stitched seam & taped seam.

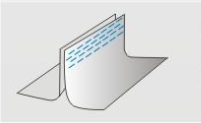

Bounded seam,this seam is an wrapped with a folded strip of similar or stronger material.This technology provides a tougher seam with superior strength.Liquid and particle barrier when compared to a traditional stitched seam. Nonwoven coveralls,disposable jumpsuit for painting,biological protection,crime scene investigation will made with bounded seam mostly.

Bounded seam,this seam is an wrapped with a folded strip of similar or stronger material.This technology provides a tougher seam with superior strength.Liquid and particle barrier when compared to a traditional stitched seam. Nonwoven coveralls,disposable jumpsuit for painting,biological protection,crime scene investigation will made with bounded seam mostly.

Ultrasonic seam,the term untrasonic seam refers to a seam created using ultrasonic welding technology, it's a highly efficient, solvent-free process that uses high-frequency sound waves to join materials together.It soft and good at elasticity, there's no holes in seam, so it's always better at water/wind proof. It benifits on nonwoven coveralls isolation gowns for medical use.